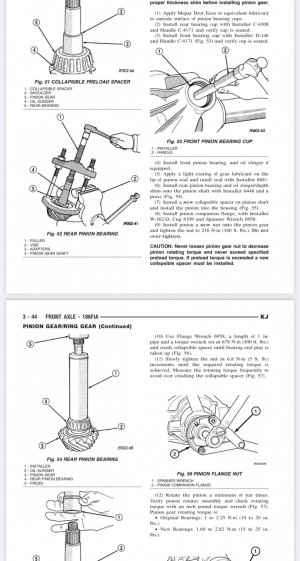

Getting ready to do final assembly on the front differential with 4.10s and DTT. When I look at the manual it states to torque pinion nut to 160 ft/lbs. that makes sense based on the 210 I started with in the rear and finished at 250. But then two steps later it states to torque to 500 ft/lbs to take all bearing end play out and crush the crush sleeve. I have a torque multiplier and can do this but seems pretty excessive and a huge jump from 160 to 500. Is this just to start the crush process?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Front differential crush washer/pinion nut torque 500 ft/lbs??

- Thread starter tyates007

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

I don't have the answer, but I got crush-sleeve eliminators instead. I don't have the experience or confidence to get this stuff right the first time.

The super 30 crush sleeve (and eliminator) is shared with a few other diffs - maybe it's the JK/KK D30. I'm away from home so I can't check what I got.

The super 30 crush sleeve (and eliminator) is shared with a few other diffs - maybe it's the JK/KK D30. I'm away from home so I can't check what I got.

Thank you. Looking forward to your replyI don't have the answer, but I got crush-sleeve eliminators instead. I don't have the experience or confidence to get this stuff right the first time.

The super 30 crush sleeve (and eliminator) is shared with a few other diffs - maybe it's the JK/KK D30. I'm away from home so I can't check what I got.

24turbo

New Member

The procedure you posted makes no sense to me.

Install the pinion as described in the procedure, but ignore the whole torque procedure for the nut.

Tighten the nut until you achieve the bearing preload noted in the procedure. I assume since you set up your rear differential you understand what is involved in measuring rotating torque of the pinion. Personally I would shoot for 15 in lbs. Every other differential Ive ever build had a spec of 10-15 in lbs for new bearings, so 25 seems to me to be a lot.

Once you achieve the proper preload, you are done. Leave the nut alone and definitely do not back it off and re-torque. If you overtightened the bearings, the easiest way will require you to get a new crush sleeve and start over. (also have a look at the races and make sure that when you overtightened it didnt leave indentations-been there, done that)

The actual amount of torque required to crush the sleeve is completely irrelevant. That number is what it is. It will easily be more than 160 ft lbs. The important part is you applied enough torque to the nut to crush the sleeve to get the proper bearing preload.

Using a torque multiplier helps this process as you can do much finer adjustments and "sneak up" on the bearing preload. As you probably know once you start getting preload on the bearings it takes very little movement of the nut to make a big difference.

If you install a crush sleeve eliminator kit, then the torque on the nut becomes relevant. It is a nice upgrade, but if you do the install correctly, the crush sleeve performs just fine.

Install the pinion as described in the procedure, but ignore the whole torque procedure for the nut.

Tighten the nut until you achieve the bearing preload noted in the procedure. I assume since you set up your rear differential you understand what is involved in measuring rotating torque of the pinion. Personally I would shoot for 15 in lbs. Every other differential Ive ever build had a spec of 10-15 in lbs for new bearings, so 25 seems to me to be a lot.

Once you achieve the proper preload, you are done. Leave the nut alone and definitely do not back it off and re-torque. If you overtightened the bearings, the easiest way will require you to get a new crush sleeve and start over. (also have a look at the races and make sure that when you overtightened it didnt leave indentations-been there, done that)

The actual amount of torque required to crush the sleeve is completely irrelevant. That number is what it is. It will easily be more than 160 ft lbs. The important part is you applied enough torque to the nut to crush the sleeve to get the proper bearing preload.

Using a torque multiplier helps this process as you can do much finer adjustments and "sneak up" on the bearing preload. As you probably know once you start getting preload on the bearings it takes very little movement of the nut to make a big difference.

If you install a crush sleeve eliminator kit, then the torque on the nut becomes relevant. It is a nice upgrade, but if you do the install correctly, the crush sleeve performs just fine.

Thank you. I planned to do just as you shared. My manual is a 2003 and there is a lot of discrepancies in it for torque on a lot of things. It will show one torque spec in the summary at the first of the chapter and then say something completely different in the steps in the chapter. It is a FSM as well so for normal fasteners I just use common torque values. Looking at the size and shape of the front crush sleeve I would not think it would take as much torque to start crushing as the rear which is what really threw me off @ 500 ft/lbs.The procedure you posted makes no sense to me.

Install the pinion as described in the procedure, but ignore the whole torque procedure for the nut.

Tighten the nut until you achieve the bearing preload noted in the procedure. I assume since you set up your rear differential you understand what is involved in measuring rotating torque of the pinion. Personally I would shoot for 15 in lbs. Every other differential Ive ever build had a spec of 10-15 in lbs for new bearings, so 25 seems to me to be a lot.

Once you achieve the proper preload, you are done. Leave the nut alone and definitely do not back it off and re-torque. If you overtightened the bearings, the easiest way will require you to get a new crush sleeve and start over. (also have a look at the races and make sure that when you overtightened it didnt leave indentations-been there, done that)

The actual amount of torque required to crush the sleeve is completely irrelevant. That number is what it is. It will easily be more than 160 ft lbs. The important part is you applied enough torque to the nut to crush the sleeve to get the proper bearing preload.

Using a torque multiplier helps this process as you can do much finer adjustments and "sneak up" on the bearing preload. As you probably know once you start getting preload on the bearings it takes very little movement of the nut to make a big difference.

If you install a crush sleeve eliminator kit, then the torque on the nut becomes relevant. It is a nice upgrade, but if you do the install correctly, the crush sleeve performs just fine.

24turbo

New Member

If the crush sleeve doesnt take much torque to crush I would be weary of it (not sure where you sourced it from). I cant see any reason why it would be less stout than the rear one. A little blue loctite may not hurt as well, because you dont want that nut backing off. It will destroy the crown/pinion in no time.

If it was sourced from somewhere reputable and it seems "weak", the eliminator kit would be the way to go. Good luck

If it was sourced from somewhere reputable and it seems "weak", the eliminator kit would be the way to go. Good luck

Last edited:

Thank you. Looking forward to your reply

I confirmed the crush sleeve interchange is with the JK. This should be it

Crush sleeve eliminator for JK Dana 30 & 44 front | SK CSJK-F | RANDYS Worldwide

Crush Sleeve Eliminator Solid Spacer Kit for JK Dana 30 and Dana 44 Front

Sorry, did not mean it felt weak. Just meant it did not look like it would take double the torque to crush as the one in the rear 8.25 axle. Appreciate your help and info. I have an eliminator kit for my 2008 JK with a Dana 30 in it that I have not installed yet. I will have to check and see if it is compatible with the KJ. I am pretty sure the crush sleeves are the same part number.If the crush sleeve doesnt take much torque to crush I would be weary of it (not sure where you sourced it from). I cant see any reason why it would be less stout than the rear one. A little blue loctite may not hurt as well, because you dont want that nut backing off. It will destroy the crown/pinion in no time.

If it was sourced from somewhere reputable and it seems "weak", the eliminator kit would be the way to go. Good luck

Thank you!I confirmed the crush sleeve interchange is with the JK. This should be it

Crush sleeve eliminator for JK Dana 30 & 44 front | SK CSJK-F | RANDYS Worldwide

Crush Sleeve Eliminator Solid Spacer Kit for JK Dana 30 and Dana 44 Frontwww.randysworldwide.com

CheddarGau

Full Access Member

Yeah the torque spec vs real world torque required to get the correct pre-load aren't the same haha. 24Turbo is correct, crank it down until you have correct pre-load and you're good. Now in the real world when doing a leaking pinion seal, use a torque wrench and check the torque of the pinion nut, compare it to the spec of the pinion "crush spec" and add 10ft lbs if you aren't replacing the crush sleeve. It's not correct, but it's commonly done by many of us in the industry. You can check pre-load but it's almost always correct.Sorry, did not mean it felt weak. Just meant it did not look like it would take double the torque to crush as the one in the rear 8.25 axle. Appreciate your help and info. I have an eliminator kit for my 2008 JK with a Dana 30 in it that I have not installed yet. I will have to check and see if it is compatible with the KJ. I am pretty sure the crush sleeves are the same part number.

24turbo

New Member

When I replace a seal I do it slightly different. I make a good quality scribe mark on the nut and yolk. When re-assembling I tighten the nut slightly past the scribe mark (1/64 of a turnish). This assures you have reached the full torque required to crush the sleeve (essentially as tight as it can be) and puts a slight extra preload on the bearings. The bearing will be considered "used" and applying a slight extra preload will not affect them.

I dont think there is any way to fully predict what torque is required to keep the nut from backing off as there are too many variables with the crush sleeve. The way you do it is common and is by no means the wrong way to do it, but Ive never had a problem doing it my way and feel more comfortable doing it that way.

As for the "real world way of doing it", as far as Im concerned there is way more risk of something going wrong if you replace the crush sleeve, as opposed to just changing the seal and leaving the crush sleeve alone. Also you cant accurately judge the preload with the differential fully assembled as you have all the drag of the carrier/axles etc.

I dont think there is any way to fully predict what torque is required to keep the nut from backing off as there are too many variables with the crush sleeve. The way you do it is common and is by no means the wrong way to do it, but Ive never had a problem doing it my way and feel more comfortable doing it that way.

As for the "real world way of doing it", as far as Im concerned there is way more risk of something going wrong if you replace the crush sleeve, as opposed to just changing the seal and leaving the crush sleeve alone. Also you cant accurately judge the preload with the differential fully assembled as you have all the drag of the carrier/axles etc.

JeepJeepster

Full Access Member

That cannot be correct. I installed 4.10's in my front diff and did not get anywhere near that. Pretty sure I recall torqueing to 160 then torquing in 5lb increments till the play was gone. Then I torqued till I got the desired rotating torque.

Gotta be a typo.

Gotta be a typo.

Last edited:

Thank you. I plan to do the same. Seemed pretty high to me as well.That cannot be correct. I installed 4.10's in my front diff and did not get anywhere near that. Pretty sure I recall torqueing to 160 when torquing in 5lb increments till the play was gone. Then I torqued till I got the desired rotating torque.

Gotta be a typo.

Reassembled tonight and crush sleeve although tough was not 500 ft/lbs tough as mentioned. It took a lot of force to start the crush and then moved fast. I set the rear at 20 in/lbs and was shooting for that on the front as well. It went from 15 to 25 in one jump. This is right at the top end of the specs for new bearings. It rotates smooth with no rough spots in both directions. I would love your thoughts on being at the top end of the specs. Am I good to go or would I be better off redoing at a little less preload?

Thank you. That was my thought as well. I know on when I was looking at specs on my wrangler Dana 30 the preload for new bearings was 20-40 in/lbs. I realize this is a different beast but figured I would be fine. Appreciate the response.It's still in spec & it's only going to wear loose so I'd leave it.

Similar threads

- Replies

- 4

- Views

- 2K

- Replies

- 4

- Views

- 3K

- Replies

- 47

- Views

- 15K

- Replies

- 8

- Views

- 5K

Latest posts

-

-

-

-

More Information Regarding Kj Renegade Roof foglight mounting

- Latest: KjBuckMobile

Members online

Total: 177 (members: 7, guests: 170)